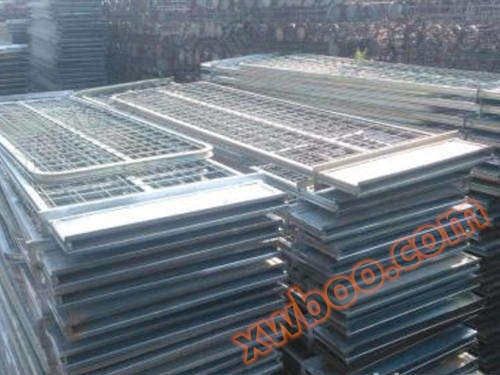

Bamfufin nau'in ƙura kawar da skeleton ne da amfani da kayan aiki daya walda gyara, da siffofin: walda karfi, bayyanar m da daidai. Bamfufin nau'in ƙura kawar da kwalliya ne kwalliya na tace jakar, ingancin ƙura kawar da kwalliya kai tsaye ya shafi aikin yanayin tace jakar da rayuwar aiki.

Bamfufin nau'in ƙura kawar da ƙashin shine kwalliya na tace jakar, ya kamata ya zama mai haske, mai sauƙi don shigarwa da kiyayewa, ingancin bamfufin nau'in ƙura kawar da ƙashin kai tsaye ya shafi tace jakar yanayin da rayuwar aiki.

Bamfufin nau'in ƙura cirewa skeleton na ƙura mai yawan ƙura da ke dauke da fiber da ƙura cirewa tsarin da aka yi amfani da ƙura cirewa daban-daban ne da ƙura gaba ɗaya, akwai nau'ikan aiki na ƙura cirewa na masana'antar masana'antu, wato, tacewa tsarin da centrifugal rabuwa tsarin.

Ana amfani da baƙofa-irin ƙura mai cirewa mafi yawa a cikin mai cire ƙura mai lantarki, mai cire ƙura mai lantarki shine na'urar da ke ɗaukar ƙura a cikin hayaki ta hanyar tsabtace lantarki. Yana da kyau kayan aiki don tsabtace masana'antu exhaust gas.

An yi amfani da tsarin sarrafawa don yin amfani da rukunin ƙura mai nau'i, zai iya waƙa isasshen rayuwar aiki da shekaru, ingancin aiki mai isasshen. Kurar tacewa jakar kwalliya yana da kyau tsari halaye da kuma aiki, saboda amfani da yumbu dumama kayan da atomatik thermostatic halaye da kuma mafi kyau aiki rufi zafi juriya kayan, tare da kyau tsari zane, da al'ada aiki rayuwa har zuwa 5 ~ 10 shekaru. Yi amfani da waya na ƙarfe ko bakin karfe waya tare da isasshen ƙarfi da karfe, galvanized, spraying, silicone da sauran hanyoyin sarrafawa. Kayan kwalliya da aka sarrafa ta fasahar silicon zai iya maye gurbin kayan kwalliya na bakin karfe, wanda zai iya rage farashin kulawa na kayan aiki.

The tacewa ƙura cirewa tsari ne m amfani da wani gajeren nesa kama tsari kamar tacewa sakamakon, yaduwa sedimentation, kai tsaye kama, inertia haɗuwa da kuma static adsorption. Lokacin da ƙura iska ta hanyar grid, masana'antu, non-woven masana'antu, kumfa filastik da sauran tacewa, ƙura a ciki ko farfajiyar samar da ƙura layers, da kuma kama tacewa layers samar da ƙura a saman layers, sa shi raba daga iska gudu. Tare da ƙarfin ƙura layer, ana buƙatar lokaci ƙura layer don ci gaba da cire ƙura tsari. Ana rarraba kayan masana'antu fiber dust remover daban-daban ta hanyar tsarin kayan masana'antu, kayan masana'antu fiber dust remover suna da kayan masana'antu masu tacewa, tacewa na jakar tacewa, tacewa na tacewa na tacewa, da sauransu.

Dukkanin walda points na baƙin rufi irin dust removal skeleton ya kamata walda karfi, ba a yarda da unwelding, falsified walda da leakage walda.

A surface na baƙon baƙon nau'in ƙura removal skeleton tuntuɓar da tace jakar ya kamata smooth da kuma m, ba a yarda da wani walda scars. Rashin lafiya da rashin lafiya.

Bamfufin nau'in ƙura removal skeleton ya kamata ya sami isasshen adadin zagaye da elasticity, janye bayan spacing ya kamata daidai.

An sarrafa nau'in baƙewa na ƙura mai kawar da ƙarfin mutum, an yi shi da electroplating bisa ga buƙatu daban-daban. Spraying ko Painting, kamar yadda aka yi amfani da high zafin jiki, da waje ya kamata a fili sadu da bukatun amfani da zafin jiki.

An yi amfani da tsarin sarrafawa don yin amfani da rukunin ƙura mai nau'i, zai iya waƙa isasshen rayuwar aiki da shekaru, ingancin aiki mai isasshen.